When Heather Hulton VanTassel went looking for plastic pellets in the Ohio River in 2021, she was simply trying to establish a baseline level of contamination. A new plastics facility was being constructed nearby, and she wanted to be able to compare the prevalence of pellets — known as “nurdles” — before and after it went into operation. The “before” number would probably be low, she thought.

What she and her co-workers found, however, exceeded her expectations. “We were really shocked at the numbers we were seeing,” she told Grist.

VanTassel is the executive director of Three Rivers Waterkeeper, a nonprofit that protects the Allegheny, Monongahela, and Ohio rivers in southwestern Pennsylvania. As she and her team went about testing the river four years ago, hundreds of nurdles were coming up in each sample they pulled with their handheld trawls, a device about the size of a large shoebox. And the plastic pieces were tiny — even more so than the 5 millimeter nurdles she was used to. She had to add coffee filters to her catchment device to keep the particles from slipping through its sieves.

VanTassel’s team kept following the pellets upstream, trawl after trawl, until they eventually reached the Ohio River’s confluence with Raccoon Creek, a popular area for swimming and fishing. That’s where they found the source. An industrial stormwater pipe was transporting pellets from a Styropek plastics facility and releasing them directly into the creek. The water testers could see them flowing out “all over the vegetation,” VanTassel said, and deposited in the soil just above the water line.

That finding became the catalyst for a legal battle that has just reached its conclusion. Three Rivers Waterkeeper and the nonprofit PennEnvironment reached a landmark settlement agreement with Styropek earlier this month, following a lawsuit they filed against the company in 2023 over its contamination of the Ohio River watershed.

The agreement, which also resolves a violation notice from the Pennsylvania Department of Environmental Protection, requires Styropek to pay $2.6 million to remediate its plastic pollution, and to fund clean water projects across the state. But what makes the settlement effective, according to the plaintiffs, is not this initial penalty. It’s a requirement that Styropek must install technology to detect the release of any more plastic pellets from its facility in Monaca, Pennsylvania. If the technology finds even a single nurdle in the facility’s stormwater outfalls, the company will have to pay up.

David Masur, PennEnvironment’s executive director, said the agreement should become “a model and a blueprint” for regulators and the plastics industry. “I think they’ll have a hard time saying rationally why they shouldn’t do it [monitor their nurdle pollution] after a case like this, where the regulators and the industry are saying, ‘We agree it’s possible.’”

Nurdles are the precursors to plastic products. Manufacturers melt them down so they can be shaped into ink pens, disposable cups, or any number of other items. A water bottle, for context, is estimated to be made of about 1,000 nurdles. Styropek’s nurdles in Raccoon Creek were made of expandable polystyrene — a type of plastic that has been banned in many jurisdictions, due to its nonrecyclability and tendency to break into hazardous microplastics — destined to become things like packing peanuts, insulation for coolers, and foamy to-go containers. The company claims to be the largest expandable polystyrene producer “in the American continent.”

Due to their tininess, ranging from the size of a pinhead to that of a nubbin on a Lego piece, nurdles are liable to escape into the environment. Spills often occur during transportation — these have been documented off the coasts of Sri Lanka, South Africa, Louisiana, and in many other places — but effluent from plastic production and processing facilities is also a significant pollution source.

Once in the environment, nurdles and the fragments that break off them may get eaten by birds and marine animals, causing plastic to accumulate up the food chain as larger critters eat smaller ones. Plastic particles are associated with a range of health problems in both humans and other animals, including heart disease and immune system dysfunction, though it’s not yet clear whether these are due to the leaching of plastics’ inherent chemical additives or the tendency of other pollutants to glom onto plastic particles, or perhaps some other factor.

What’s the connection between plastics and climate change?

In the U.S., companies that want to discharge wastewater or stormwater into public waterways have to get a special kind of permit from their state’s environmental protection agency, or the federal EPA. The permit describes the types and amounts of pollutants that are allowed to be released, and anything not included on this list may be considered a violation of the federal Clean Water Act. That formed the basis of PennEnvironment and Three Rivers Waterkeeper’s lawsuit: They argued that because Styropek’s permit didn’t say anything about nurdles, releasing them into Raccoon Creek was illegal.

Part of the settlement agreement with Styropek, which is expected to be approved by the federal court for Western Pennsylvania, gives the company three years to eliminate nurdles from its stormwater outfalls, and up to two years to eliminate them from its wastewater outfalls. Should Styropek sell its facility to another company, those requirements will still apply — a crucial detail, since the company began winding down production at its Monaca facility earlier this year and reportedly plans to shut down completely in early 2026. While the facility idles, the consent decree only applies to its stormwater; the wastewater requirements will kick in if the facility resumes production.

Styropek declined to be interviewed for this story and instead sent a statement noting that it is “firmly committed to upholding the highest standards of safety, health, environmental protection, quality, and sustainability.”

There are many ways of cleaning up stormwater and wastewater, and Styropek has already begun trialing a number of technologies, including “turbidity curtains” to trap suspended plastic in its wastewater lagoons and an iron coagulant to aggregate smaller plastic particles into larger ones.

But different technology is required to know whether those interventions are actually working. Styropek’s settlement requires it to install monitoring tools that can detect nurdles down to the individual particle, and the company will incur a fine for each inspection where one is detected. For stormwater discharge, fines will increase if more than 10 pellets are detected.

Until recently, this technology didn’t exist, at least not at an industrial scale. But a similar settlement that an environmental group and private citizen reached six years ago with the Taiwanese company Formosa Plastics, whose Port Lavaca, Texas, facility was caught releasing tens of millions of nurdles into the Gulf of Mexico, set a helpful precedent. The settlement required the facility to install novel technology to its wastewater outflows, capable of detecting not only nurdles and other microplastics but also plastic powder.

Aiza José-Sánchez, president of the company Aizaco Environmental Engineering, designed that technology. She declined to say whether she’s been approached about the Styropek settlement, but she told Grist she’s made significant updates to her equipment with an eye toward installing it at other plastics facilities.

With Formosa, Aizaco’s monitoring system is installed above an underground wastewater pipeline roughly 2 miles away from the actual plastic production facility. This is so independent auditors can access it without having to enter the facility. Aizaco disinterred part of the underground pipe and connected it to a series of detectors, which could flag samples of water that might contain plastics. One of them sensed if the water was suspiciously turbid, or cloudy. Another used filters to catch particles above a certain size, and workers onsite were also keeping watch for signs of plastic contamination. Flagged samples would be tested using chromatography, a technique that separates dissolved substances out of a mixture, to confirm whether their pollutants really were plastic.

Aizaco designed tools to detect nurdles in companies’ outflows.

Courtesy of Aizaco

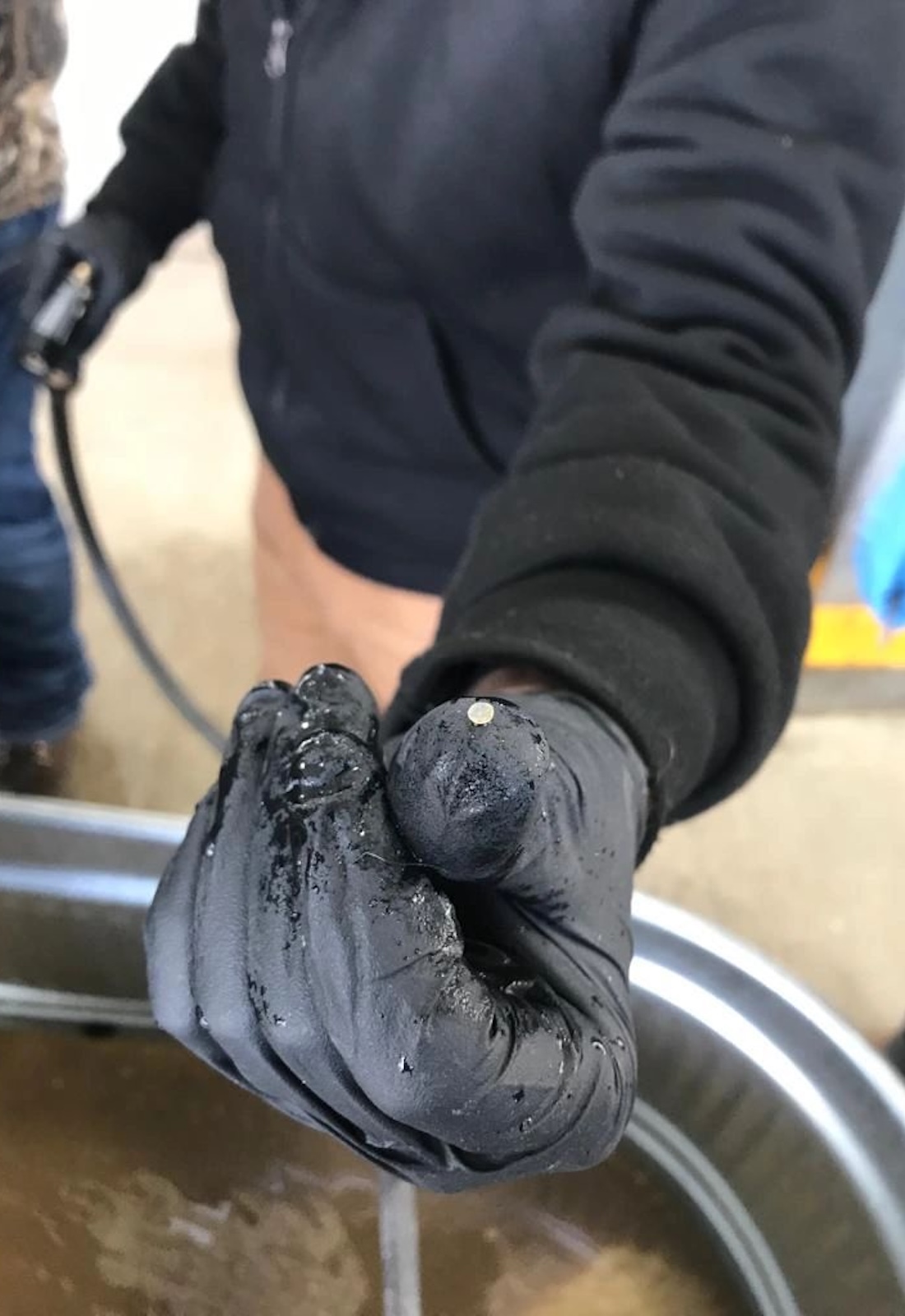

An Aizaco employee holds a nurdle detected by the company’s technology.

Courtesy of Aizaco

The system works “100 percent of the time,” José-Sánchez said. Every inspection — meaning at least three times a week, per Formosa’s consent decree — has turned up plastic pollution, she told Grist. Her company’s testing has resulted in millions of dollars of fines for Formosa.

Masur, with PennEnvironment, said the requirement of monitoring technology — supported by the Pennsylvania Department of Environmental Protection — was what made their settlement agreement such a “landmark,” more so than the $2.6 million penalty. He said he’s hoping to reinforce the precedent set in the Formosa case, which proved that it’s possible for plastic producers to set a goal of “no plastic discharges,” and then monitor their own facilities to see if they’re achieving it.

“We wanted this to be the standard under the Clean Water Act,” said Matthew Dononhue, a senior attorney at the nonprofit National Environmental Law Center, who led the complaint against Styropek.

Donohue and Masur said they couldn’t divulge whether other environmental groups were looking into their own lawsuits to demand continuous monitoring at plastics facilities. But they offered another potential path forward. Facilities with water pollution permits under the National Pollutant Discharge Elimination System have to renew their permits every five years — and when they do, the public gets a chance to give input. If enough people advocated for it, state environmental protection agencies or the federal EPA could revise facilities’ permits to include a monitoring requirement.

“As the facilities in our state have their permits come up for a renewal, we should just be taking this and dropping it right in,” Masur said.